Photo special to Alachua County Today

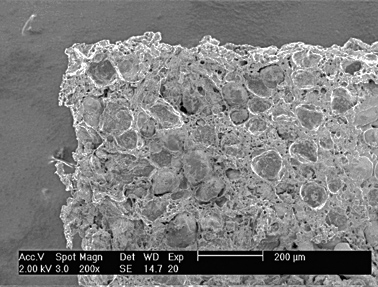

This microscope image shows the structure of the fertilizer made from recycled rubber.

ALACHUA – Dan just spent the entire day working on his lawn, laying fertilizer throughout his yard. Then just 15 minutes after he heads inside, the clouds open up and rain begins to pour down. Any chance of that fertilizer being effective would have been washed away, but a new product could change that.The company is called Eigenchem, and they are working on a new recycled waste product that acts as an efficient fertilizer, as well as an asset to the ground, even after the nutrients are released.

Alexander Oliferenko is the president and chief science officer or EigenChem Technologies Inc., and he and the company have been working in the Sid Martin Biotechnology Incubator in Alachua for the past three years.

The idea was to set out and conduct research with recycling waste and find a way to reduce the harmful impacts it can have on the environment, Oliferenko said.

“The plan was to liquefy rubber, and we actually discovered, quite accidentally, a very good nitrogen fertilizer,” Oliferenko said. “Our product is approximately 60 percent fertilizer and 40 percent rubber, after the reaction.”

It looks similar to rubber, but has a very different composition to it. It appears to have little holes or pores, and is much softer as well.

The patented product is called NTireForm, which, when broken down stands for nitrogen, tire and formula. It also can be read like entire-form, for a complete formula, Oliferenko said.

It works just like any other fertilizer, until it reacts with water. Standard fertilizers are almost completely washed away when it rains, but NTireForm absorbs the water, swells up and releases the fertilizer over time. It takes roughly two to three months for the process to completely release all the nutrients, Oliferenko said.

“After the nutrients have been dispersed into the ground, the left-over agent is incredibly absorbent,” Oliferenko said. “It is very sponge-like, and can hold almost eight times its own volume in water.”

The company began working on the product several years ago. Six months ago, it received a $150,000 grant from the National Science Foundation to test their idea and work on a proof-of-concept. Oliferenko turned in his last report for the grant two weeks ago.

“We had a good proof-of-concept and produced eight batches of material,” Oliferenko said. “We also managed to add potassium to our product, making it an even greater fertilizer than before.”

Now, the project is set to enter phase two. They have applied for another grant, this one for $750,000. For the next two years, EigenChem is going to be working alongside Jason Kruse in the Environment and Horticulture Department at the University of Florida to conduct field trials.

The main facet of phase two is going to be in commercialization and customer identification, Oliferenko said.

“I think the best application for our product in the field trials will be in turf-grass management,” Oliferenko said. “It could be golf courses or sports fields. But, it will also be an excellent product for landscaping and other lawn maintenance.”

EigenChem is a notably successful business out of the Sid Martin Biotech Incubator, said Patti Breedlove, the director of the incubator. The average stay for a company in the program is five years, but it can be more or less.

“A company must apply for admission, and not all are accepted,” Breedlove said. “Each year, they are reviewed to see if they will be renewed for another year, and graduation is customized for each company.”

The incubator provides business guidance, introduces companies to investors and helps with networking the young companies as well, Breedlove said.

The program lowers barriers to entering the market by giving access to affordable lab space and offering leadership throughout, said Nathalie McCrate, a public relations intern for the incubator.

“Any early-stage bioscience company has to overcome daunting challenges, and Sid Martin helps the likes of EigenChem translate scientific discoveries from the lab bench to the marketplace,” McCrate said.

“It truly is a great facility,”Oliferenko said. “We started with just two of us and an idea, and now we have two full-time and two part-time workers on the project.”

Oliferenko started three years ago with a problem he hoped to solve.

“It is always tempting to work on turning waste into a valued product,” he said. “We took that desire and turned it into a great opportunity.”

# # #

Email ahart@

alachuatoday.com

From tires to turf

Tools

Typography

- Font Size

- Default

- Reading Mode